Immould is often considered one of the top bucket mold manufacturers in the world. We supply insert injection molding service and overmolding molds to various companies in the bucket industry, and promise only the best products possible.

Since 2009, FOW Mould has been dedicated to the designing and manufacturing ofbucket molds.

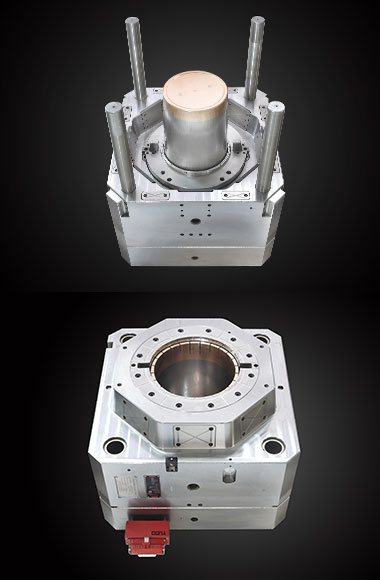

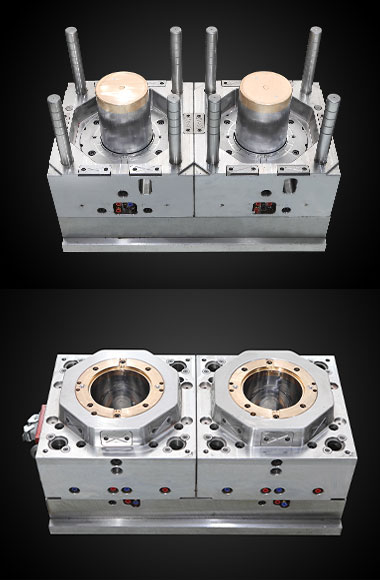

For bucket molds, the most important factor to consider is the consistency of wall thickness because uneven wall thickness will result in molding injection failure after a certain period. This requires high accuracy tools throughout the manufacturing. FOW Mould’s tooling machines are of high precision which ensures the accuracy of the molds, thus lengthen the mold life.

Other than wall thickness, the cooling system also plays a vital role in the upcoming molding injection period. The cooling system must be designed based on the bucket specifically. Improper cooling water lines might affect the efficiency of the whole injection molding process. With FOW’s 10 years experience in bucket mold, we are able to avoid mistakes and offer you the most reliable mold-making service.

Plastic Injection Molding Bucket and Mold Manufacturer

FOW Mould ventured into making bucket molds for businesses in 2009. Over time, we have gained lots of experience and expertise in designing buckets, making molds, and manufacturing plastic buckets. We have a well-put-together team of designers, engineers,

and marketing consultants that steer all our bucket injection molding projects. This cooperative approach is the secret behind

our short lead times and continued customer satisfaction.

10 Years of Experience in Bucket Mold Making

Our Plastic Bucket Injection Molding Services

We offer both product design and design optimization services. For product design, simply present to us the type of buckets that you need and our team will design them for you. In design optimization, we analyze your bucket design and enhance it for manufacturability.

Our injection mold designers develop a mold with precision as per your bucket design. They consider the materials, cooling systems, and ejection mechanisms to put forward a suitable mold design. Bucket mold designs are also optimized to achieve even wall thickness and would be modified to perfection.

Prototyping is essential because it provides tangible samples of the designs for evaluation, testing, and fine-tuning. Additionally, it is much cheaper and faster than producing actual samples. We use high-resolution 3D printers to print. They produce detailed and precise prototypes within 3 to 5 business days.

CNC machining involves producing parts or molds using computer-controlled tools. It enables the production of sample molds or parts in small quantities within a relatively short time. They are fast, accurate, and more affordable. We have invested in CNC machines to provide these services to our clients.

With cutting-edge machinery for mold making, we use superior materials to make our molds durable and highly efficient. With high tolerances of about +/- 0.02mm, our CNC machines ensure that your bucket dimensions are accurate. We’re also able to handle bulk injection molding within short times.

We offer injection molding services for customers that are unable to handle production. With the latest and streamlined injection molding processes, we keep the low-cost production and short delivery time. We handle proprietary information and client designs with great discretion and they are protected by NDA.

Injection Mold Design for Diverse Plastic Pails

FOW Mould offers a wide range of plastic bucket mold designs. They are designed for injection molding buckets that are applicable in both food and non-food industries.

On size, we can design a bucket mold that is small enough for a 1-gallon plastic bucket or big enough for a 5-gallon plastic bucket. We are also fully capable of developing custom bucket molds for other sizes within this range.

Our shape options, on the other hand, include oblong, square, rectangular, and round plastic buckets. Additionally, our design team can incorporate other features including plastic pails with lids and IML (In Mould Labelling) buckets.

Quality Materials for Plastic Pails

We pride ourselves on being a reliable plastic bucket manufacturer that use quality inputs. Our plastic bucket structures are made using materials such as HDPE, LDPE, or ABS to ensure durability and stability. The bucket handles and lids are injection molded using easy-to-mold PP and PE plastic.

All our thermoplastic materials are sourced from carefully vetted suppliers. Our list of options is quite vast but if you prefer alternative custom materials we can always source them for you. You can also rest assured that the bucket injection molding processes will run smoothly as our staff is experienced in handling different types of plastic.

Fulfill Insert Molding Part & Overmolding Needs

How We Build Plastic Injection to Support

Your Bucket Moulds Business

Injection mold design

Immould has access to highly advanced molding technology. We utilize the best molding software to ensure that all your molding needs are met. Just give us your exact specifications, and we will make your design a reality.

Injection mold engineering

Just give us your specifications, and we will have our team of engineers to design your mold for you. They will use your design, to create a very accurate prototype mold. We will customize your designs to be as accurate as possible.

Injection mold machining

All we need is your confirmation, and we will utilize our CNC machinery to create a highly detailed prototype for you. We will use this prototype as the main mold for all your products. With our computer controlled machining system, we are capable of creating quality molds for your bucket business.

Injection mold finishing & assembly

Once we get confirmation that you are satisfied with your mold prototype, we will use our injection molding technology to mass produce your bucket products. Our molding technology is very advanced and we are capable of creating a multitude of bucket copies that are perfect and serviceable.

The Advantages of Making Plastic Bucket

Moulds in Immould

High precision

Each of our molds are designed and created with incredibly high precision. By having your plastic bucket molds made by Immould, you are assured that every dimension, specification and cavity of your buckets are painstakingly designed for the best performance possible.

Short lead time

We take pride in our efficiency as a company. If you choose to work with Immould, you will be assured of a very short lead time. All we need are the exact specifications of your plastic bucket design, and we will make it a reality in no time.

Instant quote

In order to streamline the process, we have optimized our quote system. Just ask us for a quote, and we will have it ready for you in no time. We value your time, and we believe that the faster you get your quote, the sooner we could start creating a mold design for you.

Why Injection Molded Plastic Bucket Parts

for Bucket Industry

Experience

Immould has been responsible for creating over 1000 plastic bucket mold designs for various industries. This experience makes us an authority when it comes to mass producing plastic bucket molds. If you work with us, you are in good hands.

Turnkey Injection Molding Solution

What sets us apart from other plastic bucket manufacturers, is that we are the complete package. We are equipped with the necessary knowledge and machines to streamline the bucket manufacturing process.

Diverse Designs

The main reason why we have such a wide variety of plastic bucket mold designs, is because we have highly skilled designers. Just give them your designs, and they will provide you with a bevy of plastic bucket mold design options.

High Quality Plastic Buckets

If you ask any of our clients, you will be assured that all our plastic buckets are of high quality. We spare no effort or expense on innovating all of our bucket designs. We also invest in the best materials for all our products.

Best-in-class Plastic Materials for Making

Plastic Bucket Molded Parts

HDPE or High Density Polyethylene for bucket mold

LDPE or Low Density Polyethylene for bucket mold

ABS or Acrylonitrile butadiene styrene for bucket mold

Over 10+ of Experience as a Plastic Bucket Mould Maker

& Plastic Bucket Injection Company

Immould has been creating plastic buckets for over ten years, and throughout that time we have created a multitude of plastic bucket designs and so much more. Here are some of the key applications that we provide to the plastic bucket industry.

Thin Walled Container Mould

Fast Food Mould Box

Thin Mould Bowl

Plastic Paint Bucket

Utensil Mould

Disposable Drink Container Molds

Why FOW MOULD for Bucket Injection Molding

Experience

With over 40 years of experience in designing bucket molds and manufacturing, the bucket design and injection molding services we offer are adequately researched and tested. They are carefully developed through an efficient manufacturing system with low costs and short cycle times.

Turnkey Injection Molding Solution

FOW Mould is a full-service injection molding supplier. From dependable plastic mold designer, mold and bucket design to injection molding and surface finishes, we assure you of a standardized quality of buckets and timely delivery because all processes are performed in one fluid cycle under one roof.

High-Quality Plastic Buckets

Internationally certified by industry regulatory bodies, FOW Mould has and continues to invest in high-precision machinery and design software, yielding high-quality molds and end-products. Quality standards are further maintained through stringent technological checks after each stage

Previous Plastic Bucket Projects

FOW Mould has been the sole plastic injection molding supplier in more than 1000 bucket molding projects.

Each of them has been successful and has seen us become a long-standing injection mold manufacturer

for hundreds of companies. Some of our clients have since diversified their interests into furniture, baby products,

warehousing, and storage, among other industries.

We have risen to the occasion each time and supplied

them with molds and product designs for these industries. Regarding capacity, we can manufacture

900-1000 plastic injection mold units per year for your bucket and more businesses.