With our injection mold design services, we create designs that will serve as the prototype for your products. Just give us your specifications, and we will make the design for you.

Injection Mold Design Basics

-

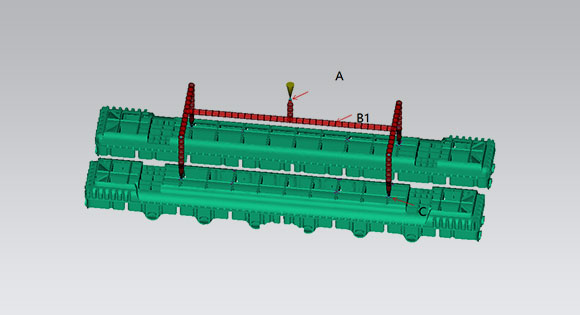

Injection Mold Gate Design

The gating system of injection mold plays a vital role in mold production and product quality. Whether the gating system design is reasonable or not has a direct impact on the quality of the products, including appearance, warping deformation, weld lines, flow marks, trapped gas and so on.

-

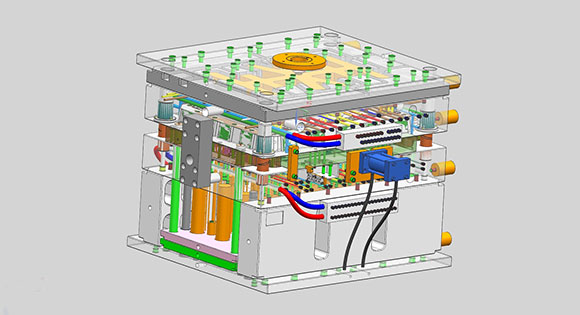

Injection Mold Cooling System Design

A well designed cooling system can significantly shorten the molding cycle, increase production capacity and reduce costs. Improper design of the cooling system will lengthen molding time, increase costs; uneven cooling will cause product warpage deformation and other undesirable.

-

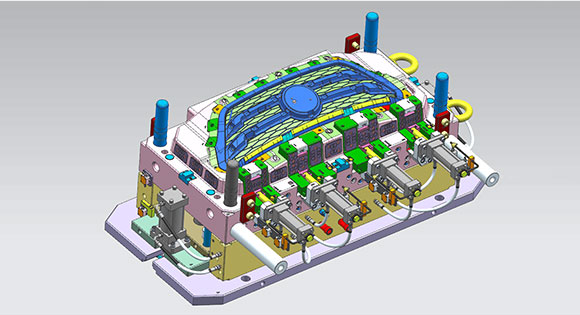

Injection Molding System Design

Unreasonable design of the molding system will affect the mold-making cycle and injection molding cycle, as well as product appearance and performance. Thus, our engineers pay 100% attention to the design of core and cavity, ensuring the best product possible.

-

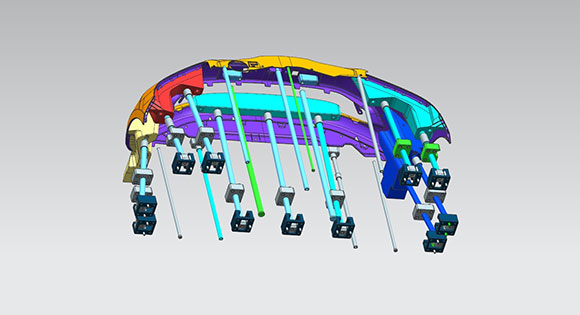

Ejection System Design

The ejection system will determine the appearance and performance of the final product, unreasonable ejection system will cause deformation, whitening, rupture and so on. With 10 years of experience in mold design, FOW got you covered.

Popular Injection Mold Designs We Specialize In

Our mould design expertise spans across several industries. FOW Mould designs injection molds for the warehousing, automobile, and home appliance industry, among numerous others. We are equipped with the latest technology and more than 40 years of experience. You can trust us to deliver the best design solutions for your project.